| Alarm Display |

Alarm Description |

Problem |

Corrective Action |

DOOR |

The door alarm indicates that the door switch is not activated and either the door is open or is not closed properly

- The door must be properly closed to initiate a sterilization cycle

|

A) Door is Not Completely Closed Defective Switch, Faulty Wire Or Connector |

A) Check That The Door Is Properly Closed

- When Door Is Properly Closed, Check Door Circuit For Continuity*

- The Door Switch Cable Plugs Into The Front Portion Of The Power Board. Refer To Panel 7

|

| - |

- |

B) Improper Alignment of Door Switch |

B) Realign Door Switch To Make Better Contact With Door Latch |

SENS |

A SENS (Sensor) Alarm Informs The User That There Is A Problem With The Chamber Sensor or Sensor Cicuitry |

A) Steam Sensor has a Bad/Poor Connection or Is Not Plugged Into Pressure/Temperature Board |

A) Check Connector and Wiring Where Unit Plugs Into Temperature/Pressure Board. Refer To Panel 7 |

| - |

- |

B) Faulty Steam Sensor |

B) Check Steam Sensor For Correct Sensor Readings. Refer To Panel 7 |

FAIL |

When FAIL Is Displayed on the Front Panel, This Indicates That There Was Not Enough Time Available To Complete The Cycle

- If the Unit Could Not Build Or Maintain Pressure , The FAIL Alarm Would Be Displayed

|

A) Not Enough Water Inside Chamber |

A) Fill Reservoir With Distilled Water. Replace Dirty Or Clogged Fill Filter

Validator 8 Fill Filter

Validator Plus 8 Fill Filter Validator 10 Fill Filter

Validator Plus 10 Fill Filter |

| - |

- |

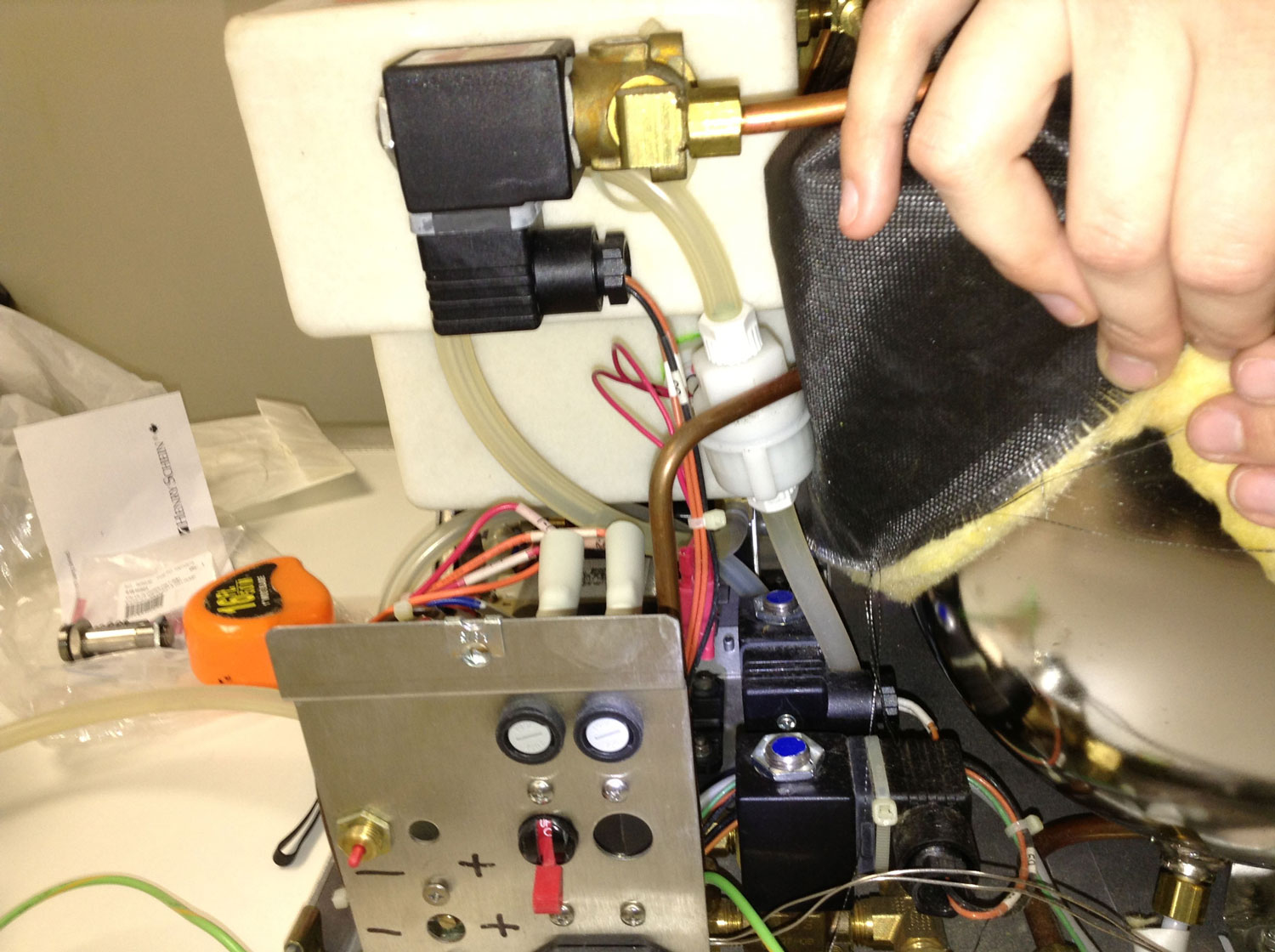

B)Valve(s), Fitting(s) Or Tubing Has Leaks |

B) Check All Valves, Tubing And Fittings For Leak. Refer To Panel 5 (Water Reservoir Leak Certification) And Panel 8 |

| - |

- |

C) Door Gasket Leak |

C) Replace Door Gasket If Cracked Or Not Properly Sealing (Shrunken)

Validator 8 Door Gasket

Validator Plus 8 Door Gasket

Validator 10 Door Gasket

Validator Plus 10 Door Gasket |

| - |

- |

D) Overloaded Chamber Causing Unit To Take Too Much Time To Reach Set Temperature/Pressure |

D) Check That There Is Sufficient Space For Steam Circulation.

Remove Excess Packs Or Instruments. Do Not Overload Instrument Trays |

| - |

- |

E) Faulty Bellows And/Or Valve Seat |

E)Bellows Should Be Compressed When Sterilizer Is Cold And Expanded Straight When Hot.

Validator 8 Bellows

Validator Plus 8 Bellows

Validator 10 Bellows

Validator Plus 10 Bellows

Valve Seat Should Be Clean And Free Of Nicks & Scrapes. Replace If Necessary

Validator 8 Valve Seat

Validator 10 Valve Seat |

| - |

- |

F) Sterilizer Countdown Interrupted For More Than 3 Minutes Due To Steam Leak (Pressure Less Than 206kPA) |

F) Check All Valves, Tubing, Fittings & Door Gasket For Steam Escaping.

Repair Or Replace As Necessary. Refer To Panel 5 (Water Reservoir Leak Indentification) And Panel 8 |

| - |

- |

G)Improper Leveling Of Unit |

G)Adjust Front Leveling Feet Gap -3/4" - 7/8" |

| - |

- |

H) Missing Or Damaged Leveling Feet |

H) REPLACE AND ADJUST GAP IF NECESSARY

Validator 8

Validator Plus 8

Validator 10

Validator Plus 10 |

| - |

- |

I)Heater Has No Power Or Partial Power. Overheat Thermostat Defective |

I)Check That Overheat Thermostat Is Closed Replace If Necessary. (Refer To Panel 7)

Validator 8

Validator 10

|

| - |

- |

J)Triac Defective |

J)Check Resistance Of Triac. Click Here For An Easy Test Of The Triac

Replace If Necessary. Refer To Panel 7

Validator 8 Triac

Validator 10 Triac |

| - | - | K) Heater Defective |

K) Check Resistance Of Heater. Replace If Necessary Refer To Panel 7

Validator 8 Heater

Validator 10 Heater |

PRES |

A PRES (Pressure) Alarm Appears If The Pressure Displayed Reaches 225 kPA.

This Usually Happens On The First Cyle When The Steam Sensor Body Is Cold.

This Is The Result Of The Steam Temperature Lagging Behind The Pressure In The Chamber Of The Sterilizer. | A)Pressure To High In Chamber. Verify By Running Another Cycle.

If Alarm Repeats, Check For Faulty Pressure/Temperature Board | A)If RPI Pressure/Temperature Board Is Installed. Replace Using Part # PCB098

Validator 8

Validator 10

If OEM Pressure/ Temperature Board Is Installed, Replace Using Pressure/Temperature Conversion Kit (Part # PCK149)

Validator 8

Validator 10

|

| - |

- |

B) Faulty Steam Sensor |

B) If RPI Steam Sensor Is Installed. Replace Using Part # PCS 100

Validator 8

Validator 10

If OEM Steam Sensor Is Installed Replace Using Pressure/Temperature Kit (Part # PCK149)

Validator 8

Validator 10 |

| - |

- |

C) Air Vent Bellows Defective Preventing Steam From Blowing By Steam Sensor Resulting In An Incorrect Temperature Reading |

C) Bellows Should Be Compressed. Not Extended When Sterilizer Is Cold. Replace Bellows If Necessary (PCB001)

Validator 8 Bellows

Validator Plus 8 Bellows

Validator 10 Bellows

Validator Plus 10 Bellows |

| - |

- |

D) Heater Always Has Power |

D)Check That Heater LED Shuts Off As Sterilizer Reaches Set Temperature. Check Resistance Of Triac (Refer To Panel 7).

Click Here For An Easy Test Of The Triac

If Resistance of Triac Is Correct, Replace The Sterilizer Supply Board. |

| - |

- |

E) No Increase In Displayed Temperature Through Sterilization Cycle. |

E) Verify That Steam Sensor Wires Are Properly Connected And Connection Is Plugged In Properly For Correct Sensor Readings.

Refer To Panel 7 For Both RPI & OEM Sensors. If Steam Sensor Is Defective And RPI Pressure/Temperature Conversion Kit Is Installed Replace Steam Sensor Using Part # PCS100.

Validator 8

Validator 10

If Steam Sensor Is Good Replace Pressure/Temperature Board (part # PCB098).

Validator 8

Validator 10

If Oem Pressure/Temperature Board And Sensor Is Installed, Replace Using Pressure/Temperature Conversion Kit (part # PCK149)

Validator 8

Validator 10

|

| - |

- |

F) OEM Temperature/Pressure Module Out Of Calbration |

F) Replace Using Pressure/Temperature Conversion Kit (part # PCK149)

Validator 8

Validator 10 |

H2O |

An H2O Alarm Displays When The Front Bottom Surface Of The Sterlizer Chamber Becomes Too Hot.

(Note: Most Likely The Chamber Has Run Dry Or There Is An Insufficient Amount Of Water For Sterilization). |

A) Not Enough Water Inside Chamber |

A) Fill Reservoir With Distilled Water. Replace Dirty Or Clogged Fill Filter

Validator 8 Fill Filter

Validator Plus 8 Fill Filter Validator 10 Fill Filter

Validator Plus 10 Fill Filter |

| - |

- |

B) Door Gasket Leak |

B) Replace Door Gasket If Cracked Or Not Properly Sealing

Validator 8 Door Gasket

Validator Plus 8 Door Gasket

Validator 10 Door Gasket

Validator Plus 10 Door Gasket (Shrunken) |

| - |

- |

C) Faulty Bellows |

C) Bellows Should Be Compressed When Sterilizer Is Cold And Expanded Straight When Hot.

Valve Seat Should Be Clean And Free Of Nicks & Scrapes. Replace If Necessary

Validator 8 Valve Seat

Validator 10 Valve Seat |

| - |

- |

D) Fitting, Tubing, Valve Block Or Valves Have Leaks |

D) Check All Fittings, Tubing And Valve Block For Leaks - Refer To Panel 5 (Water Reservoir Leak Indentification) And Panel 8 |

| - |

- |

E) Chamber Fills Properly, But Is Dry When Door Is Opened After Alarm |

E) Fill Valve Not Closing Properly. Water Is Pushed Back Into Reservoir When Pressure Starts To Increase. Refer To Panel 5 (Water Reservoir Leak Identification)

Clean And/Or Replace Fill Valve Kit. Refer To Panel 8.

Validator 8 Fill Plunger Kit

Validator 10 Fill Plunger Kit

REPLACE ENTIRE FILL SOLENOID VALVE. |

| - |

- |

F) Chamber Does Not Fill With Water During Fill Cycle. |

F) Fill Valve Clogged Or Staying In Closed Position. Clean, Rebuild And/Or Replace Fill Solenoid Valve. Refer To Panel 8

Validator 8 Fill Plunger Kit

Validator 10 Fill Plunger Kit |

| - |

- |

G)Defective Or Incorrectly Installed Surface Sensor |

G) Verify Surface Sensor Reading - Refer To Panel 7.

Validator 8 Surface Sensor

Validator 10 Surface Sensor

Be Sure Sensor Is Mounted Perpendicular To Chamber - See Panel 4 |