Description

Part #RPT954-9401

BELT TENSIONER TESTER

- Range: 0-35 lbs (0-15.9 kg) with a span of up to 170" lg. or belt deflection of up to 2.75"

- Includes: Pocket clip and clear storage tube.

- Also available: O-Ring (Part #RPO302) and O-Ring (Part #RPO315)

Model This Part Fits: Midmark Power Vac G10 Vacuums

This Belt Tension Tester measures the belt tension of most 'V' belts. Consult the OEM or the belt manufacturer for the recommended belt tension for each drive system

Specifications:

- Force Range: 0-35 lbs and 0-15.9 kg

- Tension Range: 0-560 lbs and 0-255 kg

- Recommended for use on single strand belts up to 1" wide. Use on 3V-3VX, 5V-5VX, and 8V belts with force ranges of 35 lbs (or 560 lbs tension) or less as well as A, B and C style belts. Tester can be used on any single strand belts that fall within the force range listed above.

- The Belt Tension Tester uses the universally accepted method of determining belt tension by deflecting the belt 1/16" per 1" of span. This will result in an "F" over "T" (Force/Tension) ratio of 1 to 16. Therefore, the maximum tension capability of this instrument is 16 times 35, or 560 lbs

To verify the belt tension, use the tester as follows: WARNING! Remove power from motors and pumps. Some motors may be thermally protected with an automatic reset. Unit may start without warning.

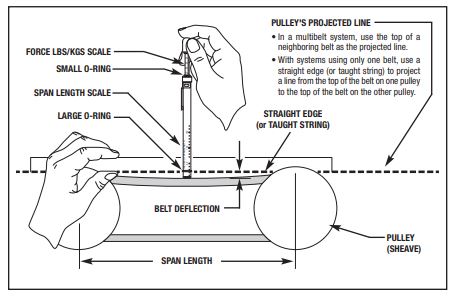

- Measure the length of span from pulley (sheave) to pulley.

- Set the bottom of the large o-ring to the measured span number on the "Inches of Span Length" scale marked on the side of the tester body.

- Slide the small o-ring down the spring loaded plunger shaft and up against the flange of the body (to the 0 lbs/kg position).

- Locate the pulley's projected line for use as a reference point during tension measurement. In a multibelt system, use the top of a neighboring belt as the projected line. With systems using only one belt, use a straight edge (or taught string) to project a line from the top of the belt on one pulley to the top of the belt on the other pulley.

- Place the tester at the center of the span and push on the rubber bumper tip deflecting the belt until the large o-ring on the body of the tester is in line with the pulley's projected line (as defined in Step 4).

- Read the number of pounds (or kilograms) force indicated by the small o-ring on the plunger shaft. Multiply this number by 16 to determine the belt tension in lbs/kg. If force and deflection are known, use the tester as follows: WARNING! Remove power from motors and pumps. Some motors may be thermally protected with an automatic reset.

Warning Unit may start without warning

- Using the inch scale, set the bottom of the large o-ring to the known deflection value.

- Slide the small o-ring down the spring loaded plunger shaft and up against the flange of the body (to the 0 lbs/kg position).

- Locate the pulley's projected line for use as a reference point during tension measurement. In a multibelt system, use the top of a neighboring belt as the projected line. With systems using only one belt, use a straight edge (or taught string) to project a line from the top of the belt on one pulley to the top of the belt on the other pulley.

- Place the tester at the center of the span and push on the rubber bumper tip deflecting the belt until the large o-ring on the body of the tester is in line with the pulley's projected line (as defined in Step 3).

- Read the number of pounds (or kilograms) force indicated by the small o-ring on the plunger shaft.

SERVICE TIPS FOR V-DRIVES

- Inspect pulleys (sheaves) and replace worn or damaged pulleys. Verify pulley alignment to within 1/2°, or 0.10" per foot of center distance.

- Do not mix old and new belts on multi drive systems and do not mix belts from different manufactures on the same drive.

- The ideal belt tension is the lowest tension at which belts will not slip under peak loads. Excessive belt tension will shorten belt and bearing life.

- Run motor long enough to fully seat the belt and recheck tension.

- Keep belts free of foreign materials. Do not use belt dressing as this will deteriorate the belt causing early failure.