Spore Test Failure

Spore Test Failure

The most common reason for failing a spore test is not due to mechanical failure, but is actually due to operator error.

If your autoclave has failed a spore test, this is a good time to review your sterilization procedures with your staff.

Observe the technician who is responsible for sterilizing the handpieces and/or instruments and look for the following problem areas:

Is The Autoclave Being Overloaded?

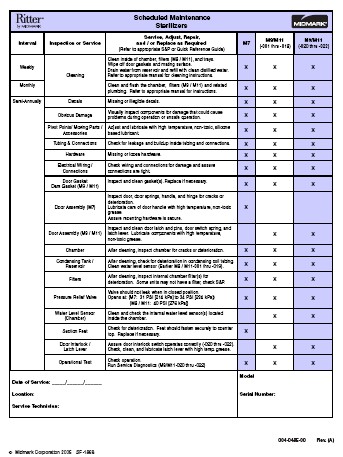

Refer to the manufacturers specifications and make sure the technician is not putting in too many items at one time.-

Is The Right Temperature Being Achieved & Maintained?

Inadequate Temperature:

- Set the temperature control knob so that it reaches and maintains 270° (or manufacturers specifications)

- Check the temperature periodically during the cycle to make sure the temperature is not fluctuating more than a couple of degrees

- If the temperature varies widely or the unit cannot maintain the manufacturer recommended temperature look for troubleshooting guides on this site for the section for your make & model autoclave

Is The Right Amount Of Pressure Being Reached & Maintained?

- Inadequate Pressure: The chamber pressure should be maintaining approximately 30psi (or manufacturer specifications)

- If pressure cannot be maintained within the recommended range, check the troubleshooting guides on this site for your unit.

- Is The Cycle Being Allowed To Run For The Right Amount Of Time?

Not Enough Time

- The normal processing cycle varies somewhat by the autoclave manufacturer. Follow the manufactures guidelines

- Shortening the cycle endangers everyone, so don’t do it

- If the temperature varies widely or the unit cannot maintain the manufacturer recommended temperature look for troubleshooting guides on this site for your unit

Improper Packaging Of Instruments

- Follow Manufacturers Recommendations

How Is Sterilization Confirmed?

- Sterilization can only be confirmed by testing for the survival of spores after a complete cycle in the autoclave

- After a spore strip is processed in a sterilizer, it is mailed to a monitoring service

- In a laboratory setting, the spore strip is aseptically removed from its protective envelope and placed in a tube of culture media. It is then incubated for 7 days

- For each of the 7 days, the tube of culture media is inspected for cloudiness

- If the spores are live and have not been killed, cloudiness is noted in the culture media. If no cloudiness is noted in the culture media, then sterilization is confirmed

Is Chemical Monitoring Sufficient?

The answer is NO!- Chemical Monitoring uses heat sensitive chemicals (not spores) to assess the physical conditions during the sterilization process

- Chemical monitoring involves the use of indicators that change color when exposed to certain temperatures

- Examples include autoclave tape, special markings on bags and pouches, and chemical indicator strips, tabs or packets

If a Chemical Indicator Changes Color, Has Sterilization Taken Place?

The answer again is NO!A chemical indicator only assesses the physical conditions (e.g., temperature) present during the cycle

When a sterilizer reaches the required temperature, it causes the chemical indicator to change color; however, it does not indicate how long the temperature was maintained. Keep this formula in mind...with the right amount of each: T+P+T (Time)(Pressure)(Temperature)= Sterilization

Categories

Important Links

- › For Missions Only

- › How To Repair Your Autoclave PC Control Board

- › OCM OCR Exploded View - UPDATED

- › Spore Test Failure

- › Sterilizer FAQ

- › Shipping Policy

- › Return/Cancellation Policy

- › Registered Trademarks

- › Disclaimer

- › Cleaning Statim Water Pump Filters

- › Payment Methods

- › International Customers

- › How To Test Autoclave Heating Elements

- › Testimonials

- › Can't Find The Door Gasket (Seal) You Need?

- › Used Autoclaves - What To Look For