Sterilizer FAQ

Autoclave Frequently Asked Questions

(For Questions Relating To Operational Problems, Please visit our Troubleshooting Guides Section)How often should I test my sterilizer?

At Least Once Per Week

The Centers for Disease Control (CDC) vol. 42/No. RR-9 calls for once a week.

Proper functioning of sterilization cycles should be verified by the periodic use of spore tests (performed at least weekly)

Note: Heat sensitive chemical indicators (those that change color after exposure to heat)are used to identify packs that have been processed through the heating cycle and do not ensure the adequacy of a sterilization cycle

Spore Testing is the only way to know for sure that the autoclave is actually sterilizing properly

Is load capacity a concern?

Yes

This is one of the most common causes for spore test failure. The quantity of instruments placed within the sterilizer chamber should never exceed the manufacturer's recommended capacity

Tabletop sterilizers, which are most frequently used in individual and group practices, have a relatively small chamber and are easy to overload

Instruments, bagged or otherwise, should not be loaded in such a manner as to inhibit the free flow of steam around them. Instruments should not be stacked on top of each other

What happens if my sterilzation cycle is interrupted?

Sterilization Is Not Complete

Interruptions of the sterilization cycle most frequently occur during a momentary power serge or failure. Effective sterilization in steam sterilizers is a specific function of time, temperature and pressure (saturated steam)

If any of these parameters is compromised, sterilization failure is likely

What is the proper time cycle?

20 Minutes - After Operating Temperature & Pressure Has Been Reached

For most steam sterilizers running at 250° Fahrenheit (121° Celsius), a 20-minute cycle is adequate. That 20-minute cycle should begin at the time the sterilizer reaches operating temperature and pressure

It is important to allow adequate warm-up time (normally 5-10 minutes) before starting the timing of the cycle

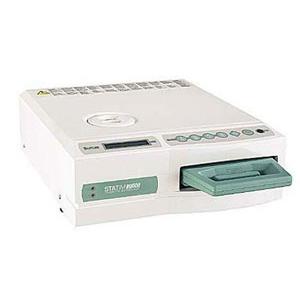

There are some steam sterilizers (ie: Scican Statim), commonly referred to as "rapid-cycle" or "flash" sterilizers, which may have a shorter cycle time (3.5 to 8 minute cycle).

What temperature do most sterilizers operate at?

250-270°F

Most steam sterilizers operate in a range between 250-270° Fahrenheit. Any lower temperature may be inadequate to achieve sterilization

Is low pressure a concern?

Yes

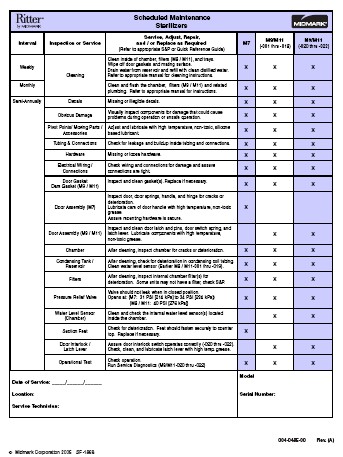

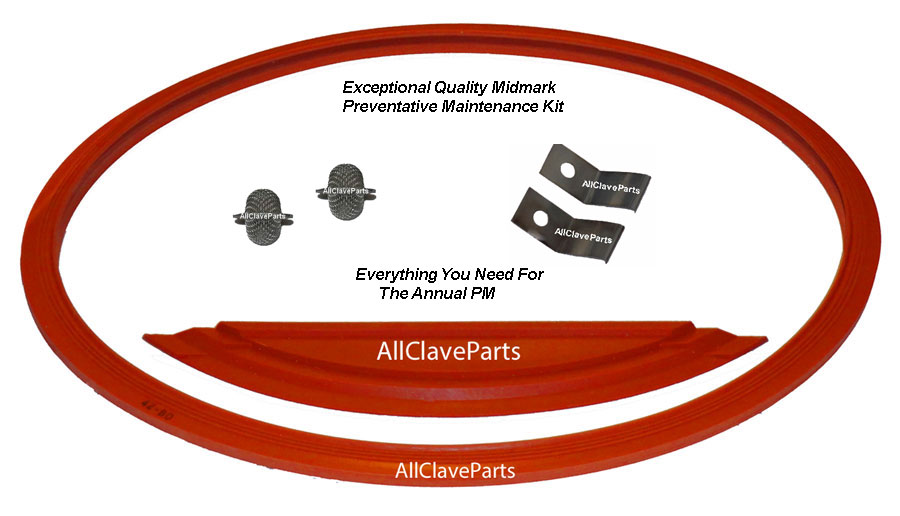

Pressure should be 15-30 psi (pounds per square inch). A frequent reason for loss of pressure is an inadequate seal of the sterilizer door gasket

The gasket may need to be cleaned with common dish washing detergent or it may need to be replaced (most door/cassette gaskets need to be changed at least every 12 months)

A "hissing" sound coming from the sterilizer door may be an indication that the gasket is not sealing properly

Is my machine venting properly?

Venting is the process, which during the warm-up time, prior to the actual sterilization cycle, cool air is displaced with the sterilizer chamber by pressurized saturated steam

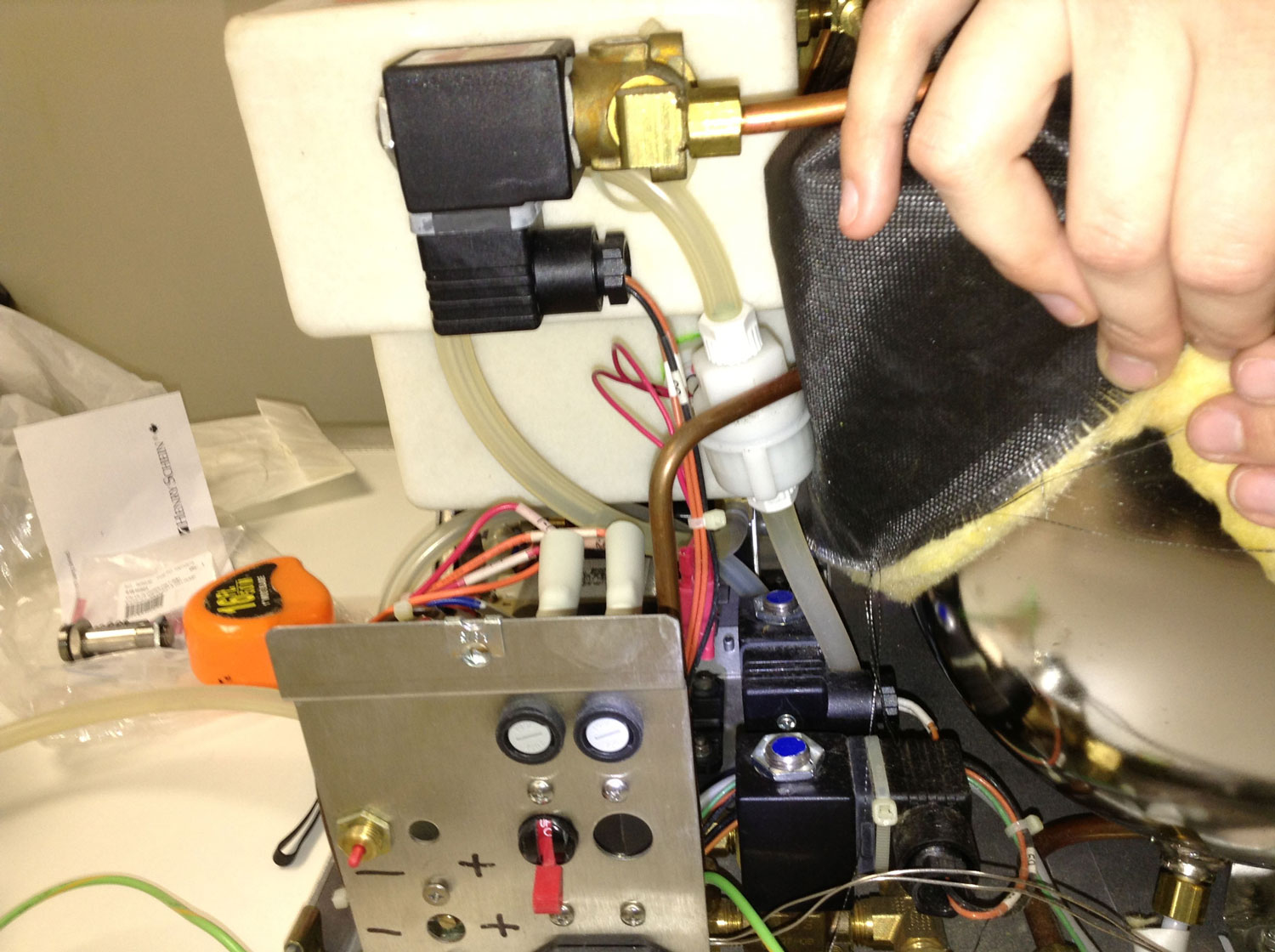

This process is achieved via a valve commonly referred to as a ":vent solenoid valve" or a Air Valve (aka Bellows)

Is tap-water okay for my sterilizer?

No

Only distilled or de-ionized water should be used in autoclaves for purposes of sterilization and maintenance related cleaning (unless your unit is desgined to operate on chemical (ie: Vapo-Sterile Solution)instead of water)

Water, other than distilled water, may be too corrosive or cause a build up of mineral deposits that can impair the function of the sterilizer

Categories

Important Links

- › For Missions Only

- › How To Repair Your Autoclave PC Control Board

- › OCM OCR Exploded View - UPDATED

- › Spore Test Failure

- › Sterilizer FAQ

- › Shipping Policy

- › Return/Cancellation Policy

- › Registered Trademarks

- › Disclaimer

- › Cleaning Statim Water Pump Filters

- › Payment Methods

- › International Customers

- › How To Test Autoclave Heating Elements

- › Testimonials

- › Can't Find The Door Gasket (Seal) You Need?

- › Used Autoclaves - What To Look For